About us | Email: info@wolf-fix.com

Languages

Find Wolfix, find your requested new materials

The cross-sectional area Af of the fiber composite material that should actually be pasted should be calculated according to the following formula:![]()

The thickness reduction factor km of fiber composite materials shall be determined according to the following provisions:

1 When preformed panels are used, km=1.0;

2 When multi-layer pasted fiber fabrics are used, the km value is calculated according to the following formula:

![]()

In the formula: Ef——design value of elastic modulus of fiber composite material (MPa), it should be adopted according to Table 4.3.5 of this code according to the type of fiber composite material;

nf——the number of layers of fiber composite material (unidirectional fabric);

tf——the thickness of single layer of fiber composite material (unidirectional fabric) (mm);

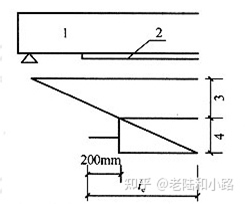

10.2.5 For the reinforcement of the normal section in the positive moment zone of the flexural member, the truncation position of the pasted fiber composite material shall be calculated from the section where its strength is fully utilized, and shall not be less than the pasted extension length determined by the following formula (Fig. 10.2.5 ):

![]()

In the formula: lc——the extension length of the fiber composite material pasting (mm);

bf——the total width (mm) of the fiber composite material pasted on the tensile surface for the beam, and the total width of the fiber composite material pasted within the board width range of 1000mm for the board;

ƒf——design value of tensile strength of fiber composite material (N/mm²), adopted according to Table 4.3.4-1, Table 4.3.4-2 or Table 4.3.4-3 of this code;

Figure 10.2.5 Paste extension length of fiber composites

1—beam; 2—fiber composite material; 3—bending moment borne by the original steel bar; 4—bending moment increment required for reinforcement

ƒf,v——Design value of bond shear strength between fibers and concrete (MPa), take ƒf,v=0.40ƒt; ƒt is the design value of concrete tensile strength, according to the current national standard "Code for Design of Concrete Structures" GB The specified value of 50010 is adopted; when the calculated value of ƒf,v is lower than 0.40MPa, take ƒf,v=0.40MPa; when the calculated value of ƒf,v is higher than 0.70MPa, take ƒf,v=0.70MPa.

10.2.6 For the reinforcement of the positive section in the negative moment zone of the flexural member, the distance between the truncation position of the fiber composite material and the edge of the support shall be determined according to the above formula according to the negative moment envelope diagram, and shall also comply with the 10.9.3 Construction provisions.

10.2.7 When flexurally strengthening the tensile surface of the T-shaped section flexural member whose flange is located in the compression zone, the fiber composite material shall be flexurally strengthened according to the calculation principles in Articles 10.2.1 to 10.2.4 of this code and the current The national standard "Code for Design of Concrete Structures" GB 50010 is used to calculate the flexural capacity of T-shaped sections.

10.2.8 When the influence of the secondary force is considered, the hysteresis strain εf0 of the fiber composite material shall be calculated according to the following formula:

![]()

In the formula: M0k——The standard value of the bending moment of the original action on the checked section of the bending member before strengthening;

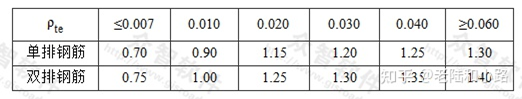

αf—calculation coefficient that comprehensively considers the change of moment arm in the crack section of the flexural member, the uneven tensile strain of the steel bar and the influence of the arrangement of the steel bar, etc., and shall be adopted in accordance with Table 10.2.8. Table 10.2.8 Calculation coefficient αf value

Note: 1 ρte is the longitudinal tensile reinforcement ratio of the concrete effective tension section, that is, ρte=As/Ate, Ate is the effective tension concrete section area, calculated according to the provisions of the current national standard "Code for Design of Concrete Structures" GB 50010 .

2 When the reinforcement stress of the original member σs0≤150MPa, and ρte≤0.05, the αf value in the table can be multiplied by the adjustment factor 0.9.

10.2.9 When it is difficult to paste all the fiber composite materials on the bottom surface (tension surface) of the beam, it is allowed to paste part of the fiber composite materials symmetrically on both sides of the beam. At this time, the side pasting area should be controlled within 1/4 of the beam height from the edge of the tension area, and the cross-sectional area Af,1 of the fiber composite material that actually needs to be pasted on both sides of the beam should be calculated according to the following formula:

![]()

In the formula: Af,b——the cross-sectional area of the fiber composite material calculated according to the bottom surface of the beam, but it needs to be pasted on the two sides of the beam;

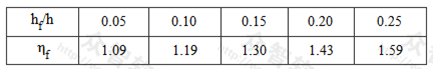

ηf——The correction coefficient considering the resultant tensile force and the change of the moment arm of the fiber composite material caused by re-attaching the beam side, which shall be adopted according to Table 10.2.9. Table 10.2.9 Correction coefficient ηf value

Note: hf is the side pasting height calculated from the tension edge of the beam; h is the height of the beam section.

10.2.10 After reinforced concrete structural members are strengthened, the increase of the flexural bearing capacity of the normal section shall not exceed 40%, and the shear bearing capacity shall be checked to avoid shear failure of the members due to the increased flexural bearing capacity prior to bending failure.

10.2.11 The reinforcement amount of fiber composite materials should not exceed 2 layers for preformed panels, and should not exceed 4 layers for wet-laid fabrics. If it exceeds 4 layers, preformed panels should be used instead, and reliable reinforcement Anchoring measures.