About us | Email: info@wolf-fix.com

Project Background

The 3-16m ordinary concrete continuous slab bridge at K129+101 was built in 1999 to cross Feng

The local road from Dengwu to Fengjian has a road width of 7 meters, a roadbed width of 8.5 meters, and an intersection angle of 100° between the road and the expressway. According to the completion data, the clearance under the bridge is greater than 4.5 meters, which meets the design requirements of the road to be handed over, but the design line was raised during the construction of the road to be handed over, and the clearance under the bridge is now less than 4.5 meters. In 2006, when some super-high vehicles passed under the high-speed bridge, the mid-span position of the side plate and bottom plate of the mid-span on both sides was scraped, the road damage area on both sides was about 1, and some main reinforcements were cut off. After the accident, the Beijing-Qin Expressway Management Office, after investigation and discussion, finally decided to repair and strengthen the 3-16-meter ordinary concrete continuous slab bridge with the maintenance column number K129+101 under the jurisdiction of Tangshan Management Office.

Analysis

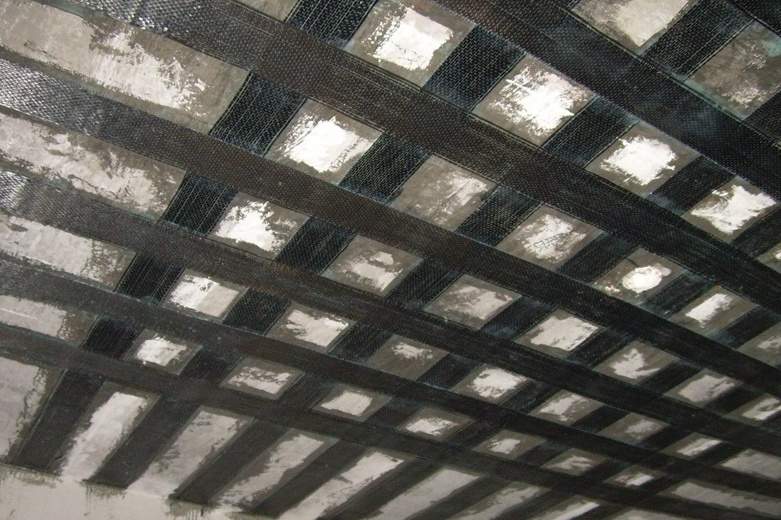

In the maintenance and reinforcement design of this project, carbon fiber cloth is used to reinforce the hollow slab, which continuously shortens the construction period and solves the problem of uninterrupted traffic during construction. It has achieved great economic and social benefits, and has been well received by relevant units.

Application

Precautions for repairing and strengthening bridges with carbon fiber cloth

1. The construction should be carried out at a temperature not lower than 5°C, and the construction and use temperature of the supporting resin should also meet the requirements. When the temperature is below 5°C, the supporting resin that can be applied at low temperature should be selected, or temperature-raising measures should be taken deal with.

2. Be prepared for the possible adverse effects of ambient temperature on resin curing during construction.

3. Reinforcement design parts should be laid out and positioned, so as to solve the concrete surface treatment and paste carbon fiber cloth sheets.

4. Strictly weigh the resin according to the ratio specified in the product manual, put it in the container, and stir it evenly with a stirrer, so that the color of the resin is uniform.

5. The primer must be accurately prepared according to the proportion specified in the manual and stirred evenly. The amount of one-time blending is limited to use within the specified time. If it exceeds the time, it must not be used again to ensure the bonding quality of the resin; If there is a raised part, it must be smoothed with a sander or a sander. Before reapplying the primer, it must be confirmed whether the primer is air-dried and not sticky.

6. In order to ensure the reinforcement effect of carbon fiber cloth, you must concentrate on pasting, paste from one side of the single width of carbon fiber cloth to the other side, and there should be no air bubbles.

7. When using the defoaming roller to roll the carbon fiber, it can be rolled in one direction or from the middle to two directions, but it cannot be rolled back and forth repeatedly, so as not to damage the carbon fiber cloth and affect the paste quality of the carbon fiber cloth.

8. Carbon fiber sheets cannot be bent during construction, and should be avoided at all times. 9. The raw materials of carbon fiber cloth with resin are flammable, explosive and volatile. Storage must be sealed, kept away from fire sources, and protected from direct sunlight.

Resin is harmful to human health. Ventilation should be maintained in the place of configuration and use. The workers on the construction site should take different labor protection measures according to different resin materials.

Conclusion

During the use of reinforced concrete bridges, due to changes in the natural environment, the frequency of use is infinitely magnified, and the damage and damage increase linearly. As time goes by, a large number of reinforced concrete bridges enter the aging period, which also leads to the deterioration of bridge structural materials and bridge bearing capacity. decline. The use of carbon fiber sheets to strengthen concrete structures is a new and emerging reinforcement technology that has matured in many developed countries in the past decade. It is also a reinforcement application technology that is increasingly concerned and developed by the domestic construction industry.

Using carbon fiber cloth to repair and strengthen reinforced concrete bridges, this repair and reinforcement technology contains theories of a wide range of disciplines such as physics, chemistry, mechanics, and material science.